Precision-Forging the Management Core, Deep-Diving Efficiency to Strengthen the Foundation --- CEPREI Experts Conduct "Little Giant" Enterprise Management Diagnosis for Shanxi Regal Metal New Materials

Under the guidance and deployment of the SME Department of the Shanxi Provincial Department of Industry and Information Technology, and to effectively enhance the development momentum of benchmark "Specialized, Refined, Unique, and New" (SRUN) enterprises, the "Little Giant" Enterprise Management Diagnosis project, part of the Shanxi SRUN SME Empowerment Action, was successfully implemented at Shanxi Regal Metal New Materials Co., Ltd. (hereinafter referred to as "Regal Metal") from June 30th to July 1st. Regal Metal is a company deeply rooted in the non-ferrous metal new materials sector. Senior experts Zheng Yuqiu and Liu Yuanguo from CEPREI Certification Center, a leading domestic authoritative certification body, went deep into the company's operations to conduct an intensive refinement process focused on "Quality Genes and Industrial Potential."

Forging Consensus, Igniting the Diagnostic Furnace

Shanxi Regal Metal New Materials Co., Ltd. is a National High-Tech Enterprise and a National-level "Little Giant" SRUN enterprise. It possesses national-level enterprise technology centers, provincial key laboratories, and other R&D platforms. As a modern enterprise specializing in the R&D and deep processing of aluminum and magnesium alloy materials, its products are widely used in high-end fields such as aerospace, automotive manufacturing, rail transportation, and 3C electronics. Upholding the corporate spirit of "Professionalism, Dedication, Pragmatism, and Truth-seeking," Regal Metal promotes the recycling and sustainable development of light metals to achieve "dual carbon" goals.

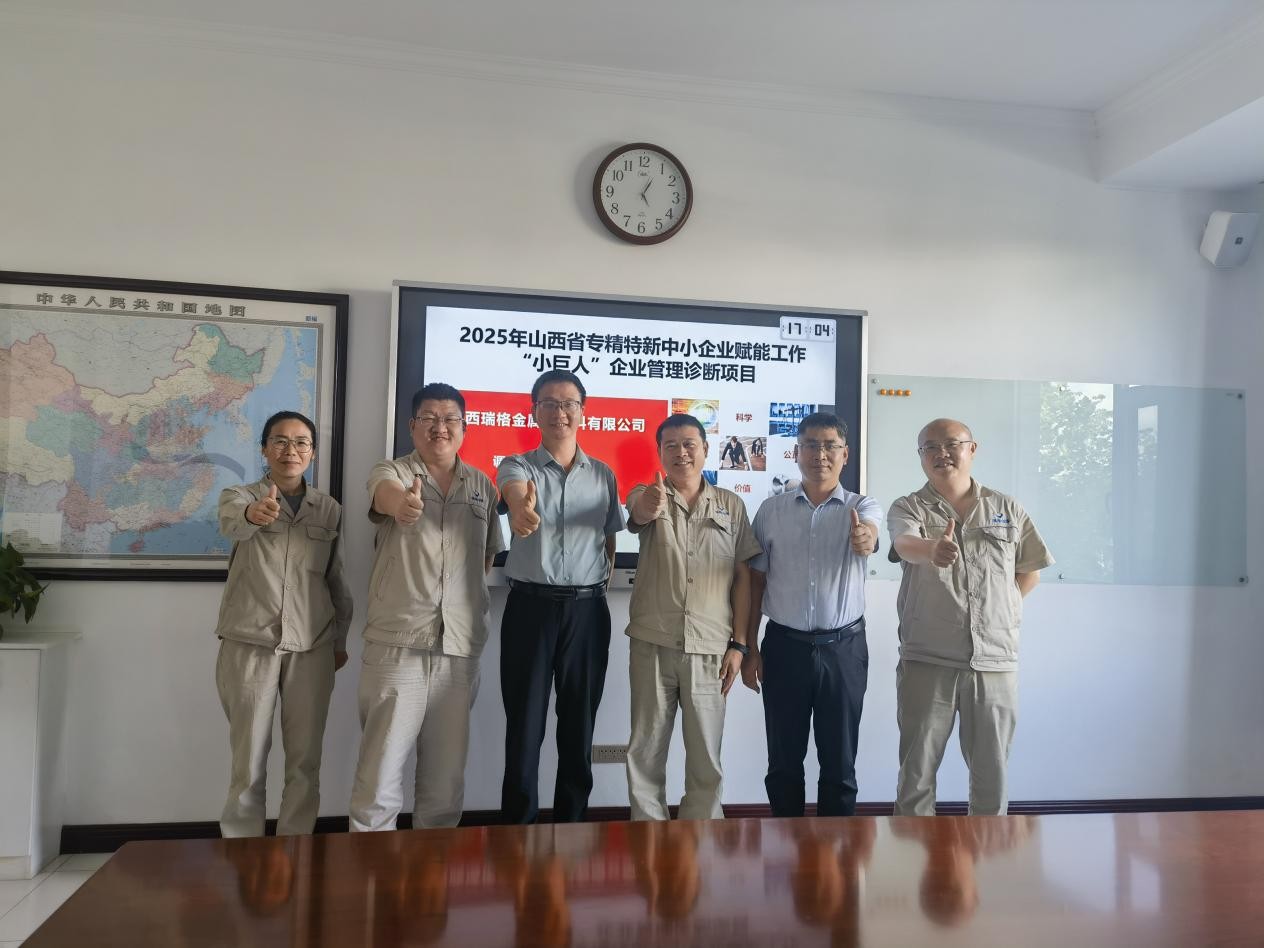

On June 30th, the Management Diagnosis Kick-off Meeting was formally held. The Deputy General Manager led the core team and all middle and senior managers to attend in full force. The Deputy GM emphasized that "excellent management, akin to the precise control of a new material's crystal structure, is the 'lattice foundation' of corporate value," demanding "molecular-level coordination" from all staff to support the experts' work. CEPREI expert Zheng Yuqiu systematically elaborated on the "Nine-Dimensional Management Lattice Refinement Framework," based on the "Guidelines for Management Improvement in Industrial Small and Medium Enterprises (Trial)."

Precise Analysis at the Furnace, Scanning Management Grain Boundaries

During the intensive two-day "Management Energy Spectrum Analysis," the CEPREI expert team employed "micro-zone probe-level" diagnostic techniques to conduct an in-depth scan of Regal Metal's nine management lattices:

- Testing the "orientation consistency" of strategic management objective transmission paths.

- Analyzing talent "lattice compatibility" and echelon "defect density" in human resource management.

- Evaluating the "phase transformation conversion rate" from innovation management technology to industrialization.

- Observing process flow "grain uniformity" and scheduling "dislocation control" in production management.

- Mapping the "stress distribution" across the entire supply chain management link.

- Testing the "surface energy barrier" of market response in marketing management.

- Analyzing the cost "composition spectrum" and capital "diffusion flux" in financial management.

- Calibrating the "crystal orientation" of multi-dimensional information for decision management.

- Measuring the thickness of the brand "corrosion-resistant layer" and the "doping effect" of social responsibility in public image management.

This process precisely mapped the "microstructural atlas" of the enterprise's management.

Forging Excellence, Co-Crafting the Blueprint for a Strong Foundation

At the diagnosis summary meeting on July 1st, CEPREI experts condensed the findings into a "Management Crystal Defect Map." They fully affirmed Regal Metal's "monocrystalline strengths" in innovation management (special material patent clusters) and production management (extreme tolerance control). Simultaneously, they pinpointed key areas for improvement: Regal Metal needs to focus on resolving the "grain boundary segregation" risk between strategic and supply chain management, strengthen the targeted cultivation of "high-purity talent" in HR and the "rapid-response mechanisms" of decision management, and enhance the "surface passivation" protective efficacy of marketing management and public image. Based on this, CEPREI experts, integrating the characteristics of the new materials industry, delivered a tailor-made systematic improvement plan—the "Nine-Dimensional Lattice Optimization Process Package"—to assist Regal Metal in forging greater organizational resilience and brand luster.

The Deputy GM stated that this diagnosis marks a crucial step in propelling management's transition from a "polycrystalline state" towards "monocrystallization." The company will establish a "Crystal Directional Growth" task force, focusing on four key lattice engineering projects:

- Enhancing coordination precision through "trigonal crystal system orientation calibration" of Strategy-Decision-Innovation management.

- Optimizing talent "conductivity" through HR "doping engineering."

- Eliminating process distortion via Supply Chain-Production management "dislocation annihilation technology."

- Boosting brand corrosion resistance by applying Public Image management "surface nano-coating technology."

The aim is to transform management grain boundaries from potential fracture points into robust energy channels, forging a monocrystalline foundation for the company's sustainable development.

This diagnosis represents a strategic turning point for Regal Metal as it advances into the "Era of Monocrystalline Management." Leveraging the provincial empowerment platform and the professional expertise of CEPREI Certification Center, the company will continue to refine its management crystal and optimize lattice constants, injecting sustained phase-transformation driving force into building the "perfect monocrystalline silicon base" for the new materials industry.